- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

|

Laser Welding Machine Video

|

Product Description

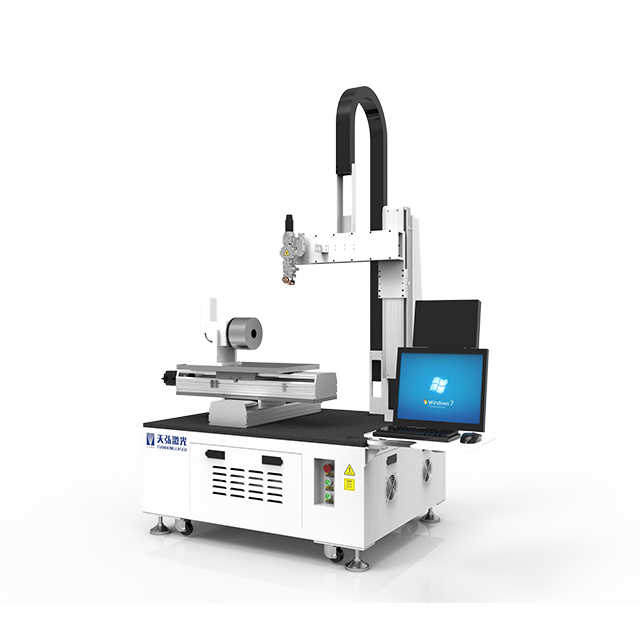

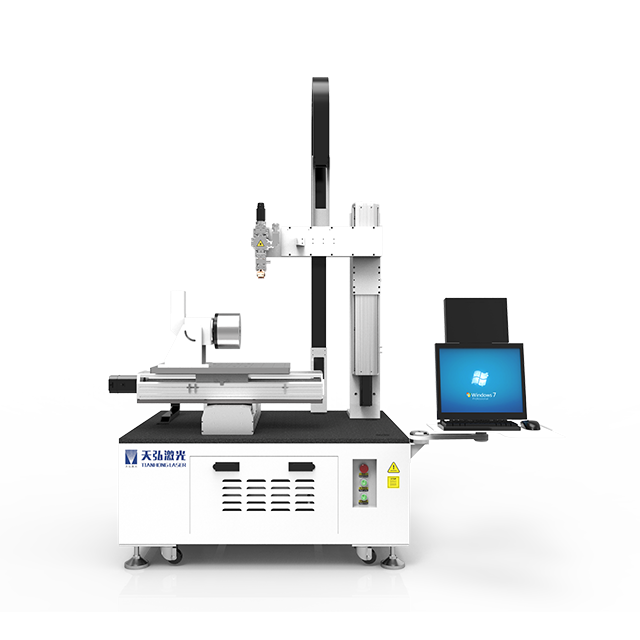

The four-axis platform laser welding machine is an advanced welding equipment that uses laser beam as the welding light source to achieve continuous welding through four-axis linkage. It uses an automatic platform, a rotating table and an automatic lifting laser beam. It is based on the welding software under the Windows platform and can be freely modified. It is simple to operate and easy to maintain. The four-axis platform laser welding machine also has automatic focusing and rotation functions, and can weld products of any shape in 3D space. It is especially suitable for high-grade stainless steel or titanium eyeglass frames, water cups, teapots, showers, stainless steel bowls, sensors, and diodes. , irregular welding of aluminum alloys, mobile phone batteries, door handles, electrical accessories and other metals.

Hardware available with fiber lasers and YAG lasers.

Adopting a four-axis three-linkage CNC system, the operation is simple and convenient, stable and reliable.

The workbench adopts high-precision modules, and the sliding table module is optional. The repeatable positioning accuracy is ±0.02mm, which effectively ensures the stability and accuracy of the welding process.

Laser welding using different processes can weld products of different lengths and sizes. It is also equipped with CCD monitoring to observe the condition of the product at any time.

Using high-precision rotating chuck, products can be fixed at different angles to achieve rotation welding.

The welding software used is simple to program and easy to operate.

CCD positioning and teaching programming is available.

|

Laser Welding Machine Parts

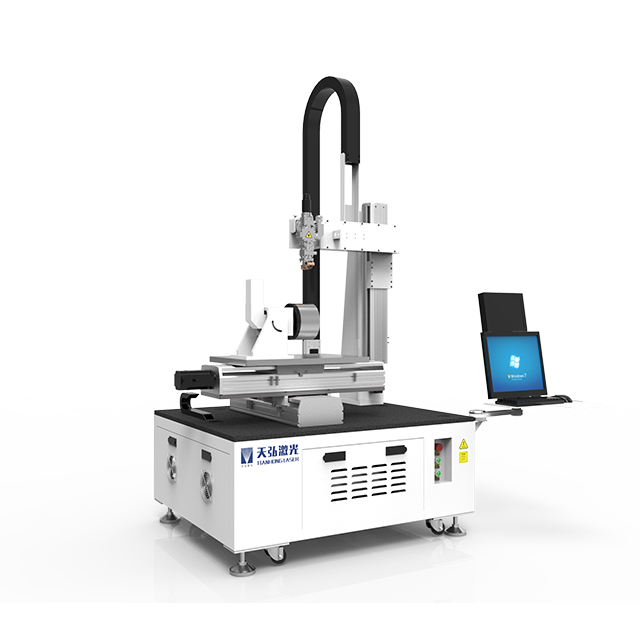

Collimated Welding Heads

Lightweight and flexible, can weld any part of the workpiece. Laser welding can realize spot welding, butt welding, stack welding, sealing welding and other welding methods for thin-walled materials and precision parts.

Multi-Axis Servo Welding Workbench

The machine adopts four-axis design, X/Y/Z workbench can be automatically adjusted, the height of the table and the laser path can also be adjusted, equipped with advanced software, flexible control of the welding trajectory movement, support for any planar trajectory and simple spatial geometry trajectory. Provide users with a higher level of portability and productivity.

CCD Vision Monitoring

High-definition CCD display allows for a better view of the welding process. Combined with aiming combination design, vision CCD acquisition and integrated infrared sensor to ensure accurate positioning. Industrial computer control system and welding-specific software provide adjustable parameter settings and multi-level waveforms.

Laser Welding Machine Software

Includes multiple languages, easy adjustments, multiple spot controls and intelligent control of weld seam tracking. Servo driver status data monitoring, laser operation status data monitoring, to ensure that the welding equipment is more stable, healthier, smarter, and can be formed into a cloud of industrial data.

Laser Source

Different laser powers and brands are optional, and can be customized. Main features: Excellent beam quality (BPP) ; Constant BPP over full power range; Using long focal length can still get a very small spot; Photoelectric conversion efficiency 30%; Maintenance free operation; Modular design, "plug and play"; Compact and easy to install.

|

Equipment Parameters

| Laser wave length | 1070NM |

| Fiber length | standard 10M Maximum 15M |

| Operate mode | Continuation/modulate |

| Welding speed range | 0~120 mm/s |

| Cooling chiller | Industrial water chiller |

| Working environment temperature range | 15~35 ℃ |

| Humidity range of working environment | <70% No condensation |

| Welding thickness recommendations | 0.5-3mm |

| Welding gap requirements | ≤0.5mm |

| Working voltage | 220 V |

|

Samples

Sample

Sample

Sample

Sample

|

The Support We Can Provide

Technical Support

1. Customer on-site technical training and guidance: provide technical training, configure and debug the equipment according to the actual situation.

2. Remote assistance: If encounter problems during use, remote assistance is available depending on the status of the problem.

Service Guarantee

1. One-year warranty: If a serious failure occurs within one year from the date of sale, the company can give one-year full machine warranty service, including replacement and repair.

2. Worry-free service guarantee: When beyond the relevant service period, the company has a lifelong equipment for customers with paid maintenance services.

Ask for the Price

|

Laser Welding Machine Video

|

Product Description

The four-axis platform laser welding machine is an advanced welding equipment that uses laser beam as the welding light source to achieve continuous welding through four-axis linkage. It uses an automatic platform, a rotating table and an automatic lifting laser beam. It is based on the welding software under the Windows platform and can be freely modified. It is simple to operate and easy to maintain. The four-axis platform laser welding machine also has automatic focusing and rotation functions, and can weld products of any shape in 3D space. It is especially suitable for high-grade stainless steel or titanium eyeglass frames, water cups, teapots, showers, stainless steel bowls, sensors, and diodes. , irregular welding of aluminum alloys, mobile phone batteries, door handles, electrical accessories and other metals.

Hardware available with fiber lasers and YAG lasers.

Adopting a four-axis three-linkage CNC system, the operation is simple and convenient, stable and reliable.

The workbench adopts high-precision modules, and the sliding table module is optional. The repeatable positioning accuracy is ±0.02mm, which effectively ensures the stability and accuracy of the welding process.

Laser welding using different processes can weld products of different lengths and sizes. It is also equipped with CCD monitoring to observe the condition of the product at any time.

Using high-precision rotating chuck, products can be fixed at different angles to achieve rotation welding.

The welding software used is simple to program and easy to operate.

CCD positioning and teaching programming is available.

|

Laser Welding Machine Parts

Collimated Welding Heads

Lightweight and flexible, can weld any part of the workpiece. Laser welding can realize spot welding, butt welding, stack welding, sealing welding and other welding methods for thin-walled materials and precision parts.

Multi-Axis Servo Welding Workbench

The machine adopts four-axis design, X/Y/Z workbench can be automatically adjusted, the height of the table and the laser path can also be adjusted, equipped with advanced software, flexible control of the welding trajectory movement, support for any planar trajectory and simple spatial geometry trajectory. Provide users with a higher level of portability and productivity.

CCD Vision Monitoring

High-definition CCD display allows for a better view of the welding process. Combined with aiming combination design, vision CCD acquisition and integrated infrared sensor to ensure accurate positioning. Industrial computer control system and welding-specific software provide adjustable parameter settings and multi-level waveforms.

Laser Welding Machine Software

Includes multiple languages, easy adjustments, multiple spot controls and intelligent control of weld seam tracking. Servo driver status data monitoring, laser operation status data monitoring, to ensure that the welding equipment is more stable, healthier, smarter, and can be formed into a cloud of industrial data.

Laser Source

Different laser powers and brands are optional, and can be customized. Main features: Excellent beam quality (BPP) ; Constant BPP over full power range; Using long focal length can still get a very small spot; Photoelectric conversion efficiency 30%; Maintenance free operation; Modular design, "plug and play"; Compact and easy to install.

|

Equipment Parameters

| Laser wave length | 1070NM |

| Fiber length | standard 10M Maximum 15M |

| Operate mode | Continuation/modulate |

| Welding speed range | 0~120 mm/s |

| Cooling chiller | Industrial water chiller |

| Working environment temperature range | 15~35 ℃ |

| Humidity range of working environment | <70% No condensation |

| Welding thickness recommendations | 0.5-3mm |

| Welding gap requirements | ≤0.5mm |

| Working voltage | 220 V |

|

Samples

Sample

Sample

Sample

Sample

|

The Support We Can Provide

Technical Support

1. Customer on-site technical training and guidance: provide technical training, configure and debug the equipment according to the actual situation.

2. Remote assistance: If encounter problems during use, remote assistance is available depending on the status of the problem.

Service Guarantee

1. One-year warranty: If a serious failure occurs within one year from the date of sale, the company can give one-year full machine warranty service, including replacement and repair.

2. Worry-free service guarantee: When beyond the relevant service period, the company has a lifelong equipment for customers with paid maintenance services.

Ask for the Price

5 / 52 Comment